Click a row below to find out more about our products!

Three Mould Press

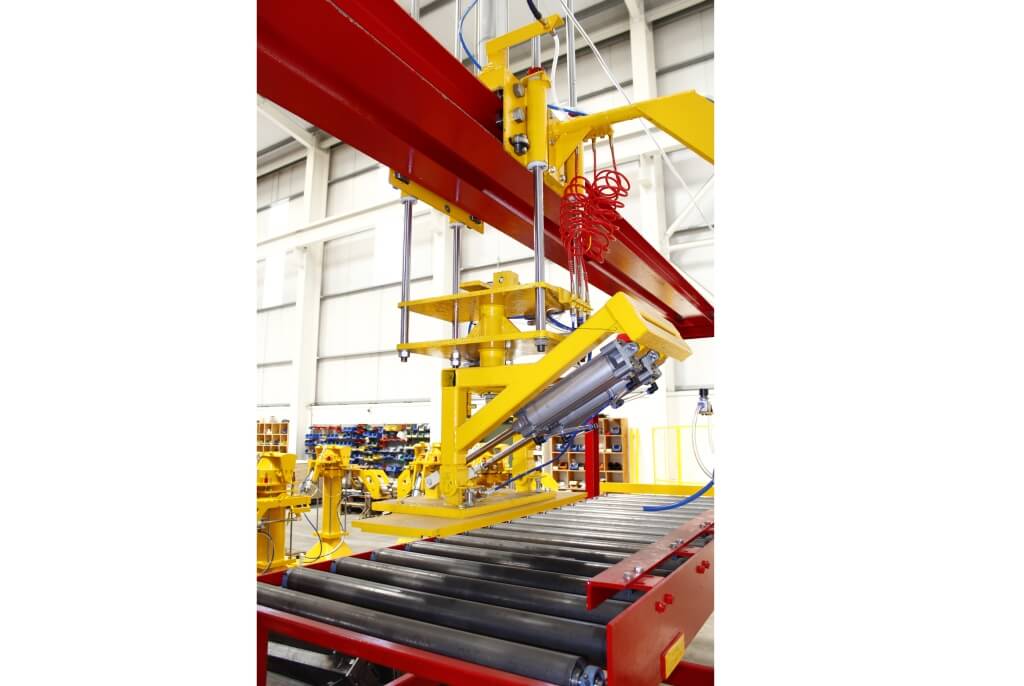

The flagship of concrete pressing is the 3-Mould Rotary Press. By using a hydraulic pressing process and rotary table system, this machine is one of the most efficient ways of producing pressed concrete products.

Forest Press supply everything you need for the 3-Mould press. From a simple seal or filter, to a gearbox, mould table, or even to complete press, we pride ourselves in our supply ability!

Whether your new to the industry, or have been pressing for years, we can keep your 3-Mould in perfect working order. Our comprehensive machining facilities and stocking systems allow us to give our customers a service and delivery they expect from the worlds No.1 !

Forest Press supply everything you need for the 3-Mould press. From a simple seal or filter, to a gearbox, mould table, or even to complete press, we pride ourselves in our supply ability!

Whether your new to the industry, or have been pressing for years, we can keep your 3-Mould in perfect working order. Our comprehensive machining facilities and stocking systems allow us to give our customers a service and delivery they expect from the worlds No.1 !

Single Mould Press

The Single Mould Press gives a cheaper tooling / set up option to the 3-Mould. It is still a 400 Ton power machine, and is capable of producing any product that the three mould can output. The actual standard mould table aperture and press daylight are identical to the three mould machine, although production is naturally slower.

This type of machine would be used for low quantity special products, such as radius, dropper, quadrant, return end kerb stones etc, although in certain parts of the world it is used as a production machine depending on market demand and competition.

Forest Press have done various modifications to the single mould machine increasing press performance. By extending the mould rails and mould moving cylinder, we are able to make a three position machine instead of a standard two. We can also modify the choke system on the mould moving cylinder to external chokes giving greater control. Along with removing the hydraulic main ram interlock valve and refitting a simple proximity switch and valve modification, we can bring your Single Mould up to its true production potential.

This type of machine would be used for low quantity special products, such as radius, dropper, quadrant, return end kerb stones etc, although in certain parts of the world it is used as a production machine depending on market demand and competition.

Forest Press have done various modifications to the single mould machine increasing press performance. By extending the mould rails and mould moving cylinder, we are able to make a three position machine instead of a standard two. We can also modify the choke system on the mould moving cylinder to external chokes giving greater control. Along with removing the hydraulic main ram interlock valve and refitting a simple proximity switch and valve modification, we can bring your Single Mould up to its true production potential.

Tooling

Whether you need slab, kerb or radius tooling, we can manufacture every type of Mouldage to your exact requirements. Conforming to British standards, or just to your own existing design, we have the perfect solution.

Quick Release Die Assemblies

Forest Press have also been at the forefront of quick release die assemblies from the very beginning. We can help you overcome the problems needed to use a paper replacement. (This has been one of the most popular items of tooling supplied to customers over the past 8 - 10 years) We have designed T Bar, Spigot, Pneumatic and Magnetic die assemblies alongside our to give the greatest choice on the market today.

The most popular has been the simple T Bar quick release system. With the use of a 6mm head filter plate and square pitch hole pattern (again jointly developed with a long standing customer), this has proved to offer a sensibly priced option that actually works! Our T Bar quick release systems have been sold all over the world and have helped with the automation of countless machines.

Why Forest Press Tooling?

We believe there are 3 reasons why you should use the Forest Press tooling systems :-

•All products Designed & Manufactured under one roof

•Cutting-edge machining techniques

•Expert advice and backup

Quick Release Die Assemblies

Forest Press have also been at the forefront of quick release die assemblies from the very beginning. We can help you overcome the problems needed to use a paper replacement. (This has been one of the most popular items of tooling supplied to customers over the past 8 - 10 years) We have designed T Bar, Spigot, Pneumatic and Magnetic die assemblies alongside our to give the greatest choice on the market today.

The most popular has been the simple T Bar quick release system. With the use of a 6mm head filter plate and square pitch hole pattern (again jointly developed with a long standing customer), this has proved to offer a sensibly priced option that actually works! Our T Bar quick release systems have been sold all over the world and have helped with the automation of countless machines.

Why Forest Press Tooling?

We believe there are 3 reasons why you should use the Forest Press tooling systems :-

•All products Designed & Manufactured under one roof

•Cutting-edge machining techniques

•Expert advice and backup

Consumables & Spares

We know how crucial keeping your press running can be.

Lost production due to failing parts or lack of spares can be frustrating to say the least!

We at Forest Press keep every part required to keep your Press in tip-top shape. Right down to the nuts and bolts, springs, seals etc, call us for the right part shipped direct to your door.

We also can supply you with seal kits, or consumable packs to keep your down-time at a minimum. Discuss your requirements with our experts, and let us show you the Forest Press way!!

Lost production due to failing parts or lack of spares can be frustrating to say the least!

We at Forest Press keep every part required to keep your Press in tip-top shape. Right down to the nuts and bolts, springs, seals etc, call us for the right part shipped direct to your door.

We also can supply you with seal kits, or consumable packs to keep your down-time at a minimum. Discuss your requirements with our experts, and let us show you the Forest Press way!!

Please visit our full desktop site, for a much more in depth look at our equipment